One of the regular operators, Jim Rollwage, brought a box of ornaments to the session today. In the spirit of the season, he decorated the dispatcher's panel.

Here's wishing you a very Merry Christmas and a great 2019!

Saturday, December 22, 2018

Thursday, December 6, 2018

Dispatcher's Panel- Part 4

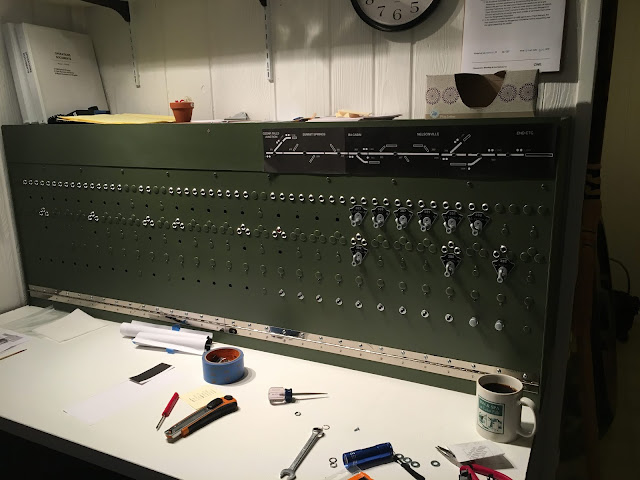

The new track model board arrived on the railroad yesterday, and all I can say is- WOW! Tyler Woodward, the graphic designer at Awards of Excellence in Dayton, OH, did an incredible job of copying my drawing and engraving the panel. Below is a shot of the results.

Drawing the model board by hand allowed me to use the appropriate US&S symbols and schematics. I used the photo below of the C&O board from the New River Subdivision as a reference source. I also used information from Mike Burgett's Control Train Components website which can be found here: http://www.ctcparts.com/.

The photo below shows a close-up of the engraving.

Now that the board is installed, I'll go back and spray all of the sheet metal screws flat black.

A special shout out to Tyler Woodward for turning the board around so quickly. He sent me proofs of the artwork just a day after I delivered the original drawing. And the time it took from the initial phone conversation to installation on the dispatcher's panel was exactly one week. Just some really great service.

The last remaining pieces of hardware for the board are the photo etched aluminum switch, signal and lock plates from Mike Burgett. More to come on this.

Drawing the model board by hand allowed me to use the appropriate US&S symbols and schematics. I used the photo below of the C&O board from the New River Subdivision as a reference source. I also used information from Mike Burgett's Control Train Components website which can be found here: http://www.ctcparts.com/.

The photo below shows a close-up of the engraving.

Now that the board is installed, I'll go back and spray all of the sheet metal screws flat black.

A special shout out to Tyler Woodward for turning the board around so quickly. He sent me proofs of the artwork just a day after I delivered the original drawing. And the time it took from the initial phone conversation to installation on the dispatcher's panel was exactly one week. Just some really great service.

The last remaining pieces of hardware for the board are the photo etched aluminum switch, signal and lock plates from Mike Burgett. More to come on this.

Friday, November 30, 2018

New East Staging Panel

The panel for the east staging yard has finally been replaced. The old panel was thrown together when I first started holding operating sessions and it has always confused the crews. In fact, the east staging yard was controlled by two separate panels which really made things interesting. And for whatever reason, I never thought to provide some type of instructions at the panels. No wonder everyone was confused!

The new panel utilizes pushbuttons for turnout routing using Gerry Alber's Signal By Spreadsheet products.

Note the westbound repeater signal on the panel. Now that CTC is in place from East Staging to Cedar Falls Junction, the dispatcher will be able to route trains through Nelsonville and beyond. The yard limits from East Staging to just west of BA Cabin have been eliminated and the Nelsonville Yardmaster will now need to contact the dispatcher in order to "open up" and access the main. The shot below of the dispatcher's panel shows the route lined through Nelsonville.

And the next shot shows the green indication on the East Staging panel. The new instructions inform the crews to turn on the power to the appropriate staging track, acquire their locomotive, and then call the dispatcher for clearance west. The crews can depart when given either a green or yellow board on the panel.

The issue with the track model board on the dispatcher's panel has been resolved, too. As I couldn't find any software that I could use, I drew it up to scale using my old drafting equipment. I laid out all of the signals, place names and turnout and lock numbers in PowerPoint and then glued them to the drawing. The end product was dropped off at the engraver's yesterday and it should be ready in about a week. It will certainly be an improvement over the Avery labels that won't stay on!

The new panel utilizes pushbuttons for turnout routing using Gerry Alber's Signal By Spreadsheet products.

Note the westbound repeater signal on the panel. Now that CTC is in place from East Staging to Cedar Falls Junction, the dispatcher will be able to route trains through Nelsonville and beyond. The yard limits from East Staging to just west of BA Cabin have been eliminated and the Nelsonville Yardmaster will now need to contact the dispatcher in order to "open up" and access the main. The shot below of the dispatcher's panel shows the route lined through Nelsonville.

And the next shot shows the green indication on the East Staging panel. The new instructions inform the crews to turn on the power to the appropriate staging track, acquire their locomotive, and then call the dispatcher for clearance west. The crews can depart when given either a green or yellow board on the panel.

The issue with the track model board on the dispatcher's panel has been resolved, too. As I couldn't find any software that I could use, I drew it up to scale using my old drafting equipment. I laid out all of the signals, place names and turnout and lock numbers in PowerPoint and then glued them to the drawing. The end product was dropped off at the engraver's yesterday and it should be ready in about a week. It will certainly be an improvement over the Avery labels that won't stay on!

Friday, November 23, 2018

Freight Car Friday

Back when I first started planning the railroad, one of my goals was to have prototypically accurate rolling stock. To accomplish this during the 1980's required a lot of kit-bashing. Fortunately, at that time there were a number of very talented modelers who were doing just that and publishing articles about their efforts. I collected all of those articles I could find about kit-bashed rolling stock that would be appropriate for my era (1976). And along the way, I kit-bashed a lot of freight cars. Many of these are dated and a bit crude by today's standards, but they remain some of my favorites. Along the lines of the Wordless Wednesdays, Throw Back Thursdays, and Front End Friday posts, I thought I would start a Freight Car Friday series of posts. Periodically, on a Friday, I'll post pictures and a story about some of the cars I've built over the years. So let's get started.

The very first subject of the Freight Car Friday posts is GM&O 47298. There was a picture of a 40' GM&O car that appeared in the August 1979 issue of Model Railroader. It was part of an article on the Fonda, Johnstown and Gloversville Railroad by Harold Russell. The car was spotted on the team track at Johnstown and a group of workers from Karg Brothers was unloading hides onto a truck. It was one of those classic 40' cars that I thought would make a great addition to the railroad.

The starting point for the car was an Athearn Blue Box 40' car. The GM&O car appeared to have the same Dreadnaught end as the Athearn car. Upon closer inspection of the article today, that's exactly what is on the car. However, when I built this car back in 1985, I chose to modify the end per an article by Jim Eager in Railroad Model Craftsman. You can see the modified end in the picture below.

The end ladders were removed and new ones added from some long forgotten source. The side ladders were cut down to match the photo and new grab irons were added to the sides and ends. A new side sill was made from styrene to match the prototype. The rivets on the side sills came from old diesel shells. They were sliced off the shells and then added to the sill by placing them in position and applying a small spec of styrene cement. This is one of my favorite tricks from the old days. The stirrup steps are staples.

All the remnants of the original door tracks were removed and new ones were fashioned from styrene and Plastruct shapes. The door is from the old Athearn Railbox kit and while not accurate, it is at least the same width as the prototype. I believe the GM&O decals were made by Champ. Unfortunately, the truck in the original photo blocked the car number and the end of the car was blocked by another boxcar. So I am absolutely certain that the number is wrong. Remember- there was no Internet in 1985 and finding the correct number for this car would have been a herculean task.

Prototypically accurate? Not really, and certainly not by today's standards. But it was a fun build and carries enough of that generic, 40' boxcar flavor from the 1970's to meet the "exempt from retirement" standard.

The very first subject of the Freight Car Friday posts is GM&O 47298. There was a picture of a 40' GM&O car that appeared in the August 1979 issue of Model Railroader. It was part of an article on the Fonda, Johnstown and Gloversville Railroad by Harold Russell. The car was spotted on the team track at Johnstown and a group of workers from Karg Brothers was unloading hides onto a truck. It was one of those classic 40' cars that I thought would make a great addition to the railroad.

The starting point for the car was an Athearn Blue Box 40' car. The GM&O car appeared to have the same Dreadnaught end as the Athearn car. Upon closer inspection of the article today, that's exactly what is on the car. However, when I built this car back in 1985, I chose to modify the end per an article by Jim Eager in Railroad Model Craftsman. You can see the modified end in the picture below.

The end ladders were removed and new ones added from some long forgotten source. The side ladders were cut down to match the photo and new grab irons were added to the sides and ends. A new side sill was made from styrene to match the prototype. The rivets on the side sills came from old diesel shells. They were sliced off the shells and then added to the sill by placing them in position and applying a small spec of styrene cement. This is one of my favorite tricks from the old days. The stirrup steps are staples.

All the remnants of the original door tracks were removed and new ones were fashioned from styrene and Plastruct shapes. The door is from the old Athearn Railbox kit and while not accurate, it is at least the same width as the prototype. I believe the GM&O decals were made by Champ. Unfortunately, the truck in the original photo blocked the car number and the end of the car was blocked by another boxcar. So I am absolutely certain that the number is wrong. Remember- there was no Internet in 1985 and finding the correct number for this car would have been a herculean task.

Prototypically accurate? Not really, and certainly not by today's standards. But it was a fun build and carries enough of that generic, 40' boxcar flavor from the 1970's to meet the "exempt from retirement" standard.

Wednesday, October 24, 2018

Where's Waldo?

Well, the rascals are at it again. During the last op session, I overheard Bill Doll ask someone if I would be able to spot the change in the scenery over in the Big Chimney area. I grimaced, but decided to wait until after the session to check it out. Based upon past history, there's no telling what may have happened and I wasn't ready to face some major calamity at the start of the session.

First, though, a little history. Over the last handful of years, a number of the regular operators have made comments about the lack of figures on the railroad. The only place you'll find anything resembling a living thing is in the cabs of the locos. I think they look really neat there. But that's it. In my opinion, figures in action mode, i.e. shoveling coal or running down the street, distract from the realism of any given scene. Figures in sedentary poses are something else, and I suppose I could live with a few of them. So by now I'm sure you know where this is headed.

The next several photos show the handy work of the rascals. Finding them is a little like playing Where's Waldo.

But wait- there's more! Not to limit themselves to mere humans, the rascals also decided to add animals!

It seems as though every time I walk into the railroad room I find another lost soul or a wayward animal. There's just no telling where they may be.

And yes, there are more. And I'm sure I'll be finding them for some time into the future. And no- it's unlikely that I'll find all of them. I'm sure a few may end up like the first two figures the rascals placed on the railroad. Unbeknownst to me, I sucked them up into the vacuum while cleaning the layout. They were the two unwitting accomplices to the campfire scene, and we all know what shenanigans that led to.

So if you ever happen to have Bill Doll at one of your sessions, be sure to ask- continually- Where's Bill?

First, though, a little history. Over the last handful of years, a number of the regular operators have made comments about the lack of figures on the railroad. The only place you'll find anything resembling a living thing is in the cabs of the locos. I think they look really neat there. But that's it. In my opinion, figures in action mode, i.e. shoveling coal or running down the street, distract from the realism of any given scene. Figures in sedentary poses are something else, and I suppose I could live with a few of them. So by now I'm sure you know where this is headed.

The next several photos show the handy work of the rascals. Finding them is a little like playing Where's Waldo.

But wait- there's more! Not to limit themselves to mere humans, the rascals also decided to add animals!

It seems as though every time I walk into the railroad room I find another lost soul or a wayward animal. There's just no telling where they may be.

And yes, there are more. And I'm sure I'll be finding them for some time into the future. And no- it's unlikely that I'll find all of them. I'm sure a few may end up like the first two figures the rascals placed on the railroad. Unbeknownst to me, I sucked them up into the vacuum while cleaning the layout. They were the two unwitting accomplices to the campfire scene, and we all know what shenanigans that led to.

So if you ever happen to have Bill Doll at one of your sessions, be sure to ask- continually- Where's Bill?

Tuesday, September 25, 2018

That Was Fun

One of the blogs that I follow is Chris van der Heide's Algoma Central. His blog posts contain a wealth of information on Canadian railroading in the 1960's up through the mid-80's in addition to very in-depth research on the AC. He is also an incredibly talented modeler and scratch-builder. Some of his recent structure and freight car projects are just beautiful. You can find a link to his blog in the Great Railroad Modeling Sites list to the right of this post.

Last week, Chris posted about making a styrene strip sorting and storage rack. Here's a link to the post: http://vanderheide.ca/blog/2018/09/23/styrene-strip-sorting-and-storage-rack/. I have been struggling for years to keep my supply of styrene strips and brass wire organized and Chris' design looked like the perfect solution. Plus, I have never used foam core board for anything before and this project looked like a good chance to try it out.

The photo below shows the modified shoe box that I have used for many years to store strip styrene and brass wire. While it doesn't look it, the strips are organized by size and part number. But as you can see, actually finding the part number and/or size requires a bit of searching. And the box is getting pretty full.

Chris provides the basic dimensions of the rack in his post and it's easy enough to come up with the rest based upon the size of the Evergreen packages. So after a little cutting and gluing with the foam core board, the new rack was ready to be placed in service!

This was a fun little project and a nice diversion from wiring up LED's for the dispatcher's panel. And I know I'll be grateful the time I reach for some brass wire or strip styrene. So thanks, Chris, for the idea!

Last week, Chris posted about making a styrene strip sorting and storage rack. Here's a link to the post: http://vanderheide.ca/blog/2018/09/23/styrene-strip-sorting-and-storage-rack/. I have been struggling for years to keep my supply of styrene strips and brass wire organized and Chris' design looked like the perfect solution. Plus, I have never used foam core board for anything before and this project looked like a good chance to try it out.

The photo below shows the modified shoe box that I have used for many years to store strip styrene and brass wire. While it doesn't look it, the strips are organized by size and part number. But as you can see, actually finding the part number and/or size requires a bit of searching. And the box is getting pretty full.

Chris provides the basic dimensions of the rack in his post and it's easy enough to come up with the rest based upon the size of the Evergreen packages. So after a little cutting and gluing with the foam core board, the new rack was ready to be placed in service!

This was a fun little project and a nice diversion from wiring up LED's for the dispatcher's panel. And I know I'll be grateful the time I reach for some brass wire or strip styrene. So thanks, Chris, for the idea!

Wednesday, September 5, 2018

Excavating

Now that the summer is over, it's time to get the railroad ready for operating sessions again. I spent most of the summer working on various pieces of the dispatcher's panel and developing all new waybills. As a result, nothing much moved over the road in about three months. There were several small problems that cropped up over the summer, and it's time to fix those and thoroughly check the railroad prior to the next operating session.

After firing up the railroad this morning, I heard a soft, humming sound over near the McHenry Coal Co. tipple at the end of the Sand Fork Branch. It appeared that one of the old Hankscraft switch motors had developed a problem of some sort. The photo below shows where the turnout that is controlled by this switch machine is located- it's next to the pole above the tunnel portal. Note the hill between the track and the aisle.

Fortunately, there is access to this switch machine in the area shown in the photo below.

Unfortunately, someone thought that this clever idea might actually allow a person to access the switch machine. Aside from the fact that the hole is behind the previously mentioned hill, there is simply no way to get to anything even remotely related to the switch machine. A quick check under the layout revealed the cursed, dreaded, abandoned west staging yard. And of course, it completely blocked any access to the switch machine in question. Sigh... This project was going to be much more difficult than I had originally imagined.

After studying the throat to the abandoned yard, it appeared that I might be able to remove it. It wasn't physically connected to the yard itself, except for the track, and it looked like there were only a handful of screws holding it the benchwork.

After much gnashing of teeth and a couple of skinned knuckles, I was successful. The photo below shows what was excavated from underneath the railroad.

The next two photos show the site of the dig. Note the staging yard tracks in the lower third of the second photo.

The new machine is now in and operating as it should. I certainly dodged a bullet on this one. And fortunately, the remaining switch machines on the Sand Fork Branch that are above the abandoned west staging yard all have access holes that can actually be used. I think. At least I hope...

After firing up the railroad this morning, I heard a soft, humming sound over near the McHenry Coal Co. tipple at the end of the Sand Fork Branch. It appeared that one of the old Hankscraft switch motors had developed a problem of some sort. The photo below shows where the turnout that is controlled by this switch machine is located- it's next to the pole above the tunnel portal. Note the hill between the track and the aisle.

Fortunately, there is access to this switch machine in the area shown in the photo below.

Unfortunately, someone thought that this clever idea might actually allow a person to access the switch machine. Aside from the fact that the hole is behind the previously mentioned hill, there is simply no way to get to anything even remotely related to the switch machine. A quick check under the layout revealed the cursed, dreaded, abandoned west staging yard. And of course, it completely blocked any access to the switch machine in question. Sigh... This project was going to be much more difficult than I had originally imagined.

After studying the throat to the abandoned yard, it appeared that I might be able to remove it. It wasn't physically connected to the yard itself, except for the track, and it looked like there were only a handful of screws holding it the benchwork.

After much gnashing of teeth and a couple of skinned knuckles, I was successful. The photo below shows what was excavated from underneath the railroad.

The next two photos show the site of the dig. Note the staging yard tracks in the lower third of the second photo.

The new machine is now in and operating as it should. I certainly dodged a bullet on this one. And fortunately, the remaining switch machines on the Sand Fork Branch that are above the abandoned west staging yard all have access holes that can actually be used. I think. At least I hope...

Friday, August 24, 2018

The Panel- Part 3

Well, I managed to get the panel and cabinet painted and some of the hardware installed. David Stewart, of Appalachian & Ohio fame, was kind enough to share with me how he finished his panel. You can see it on his website- here's a link: http://forum.aorailroad.com/t/ctc-machine-build/169. Given how nicely his panel turned out, I followed his instructions to the letter. Here's a view of the panel and cabinet.

Each of the individual switch plates is a model in and of itself. First, it has to be painted black. Then the plate has to be sanded to remove the paint from the raised surfaces. The edges of the plates also have to be filed to remove any residual paint. Next, a coat of gloss is required in preparation for the decals. Once the decals have been applied, another coat of gloss is necessary in order to seal them in place. And then they are ready to install. It appears this will take a little longer than expected...

And here is an up-close shot of the panel.

In addition to the LED's, a few pieces of hardware remain to be installed to the section above.

I'm not very satisfied with how the full page Avery labels are working for the track diagram. For whatever reason, they don't want to stay fixed in place. I'm not sure what the solution will be for this problem. One option will be to take all of the labels, once everything is laid out properly, and mount them on a separate board. That board could then be taken to a commercial firm to be used as a template for the artwork for an engraved board. More to come on this.

Next up- order the DIO cards from Signals By Spreadsheet and start wiring!

Each of the individual switch plates is a model in and of itself. First, it has to be painted black. Then the plate has to be sanded to remove the paint from the raised surfaces. The edges of the plates also have to be filed to remove any residual paint. Next, a coat of gloss is required in preparation for the decals. Once the decals have been applied, another coat of gloss is necessary in order to seal them in place. And then they are ready to install. It appears this will take a little longer than expected...

And here is an up-close shot of the panel.

In addition to the LED's, a few pieces of hardware remain to be installed to the section above.

I'm not very satisfied with how the full page Avery labels are working for the track diagram. For whatever reason, they don't want to stay fixed in place. I'm not sure what the solution will be for this problem. One option will be to take all of the labels, once everything is laid out properly, and mount them on a separate board. That board could then be taken to a commercial firm to be used as a template for the artwork for an engraved board. More to come on this.

Next up- order the DIO cards from Signals By Spreadsheet and start wiring!

Subscribe to:

Posts (Atom)